The Mills

I remember when i first sterted in the steel industry and everyone was talking about the Mills, coils and different specs i felt so lost. Its was only after someone actually gave me a brief explanation the went futher than the obvious fire needed in a huge factory called a Mill. The process from raw material that compiles the mechanical charatiristics of specific batches, which is needed for the ertificate of origin are technical details we wont even bother with for now.

We are going to focus on what happens in the Mill or needs to happen in the Mill to start the proccess of manufacturing roof sheets. First let me start by saying the Mill is where they produce the coils we need to eventually make the roof sheets. A coil is a long flat sheet rolled up to form a coil. These coils can start at 2 tons and go all the way up to 30 tons per coil. Not all coils ar the same, some are thicker, where others again thinner. The width of these coils also differ from a narrow span, standard 925 to the wide span.

I feel it is worth mentioning that these Mills go thru production phases where they will set up the entire factory to meet market demand. This means they are not always making the same spec coils or able to make every different type of specification on the market. Some Mills can handle multiple runs while others not so much. Imagine the massive undertaking it is to stop production completly so you are able to adjust the entire production line. These production lines are much bigger than one might think. Every part of the line need to be adjusted, changed and tested.

At the end of the Mill proccess you have a coil or a range of different coils to cater for different needsa nd market demands. This allows the next step in the proccess to start.

This is the coil that the Mill supply. Once you understand how a coil is made and that is is used to manufacture roof sheets you will be interested to know that many steel products are manufactured from coil, not the same coil but a coil specifically made for tubing, flatbar, angel iron or metal plates. Knowing how roof sheetsa re made is the first step to knowing the very basics in the steel industry.

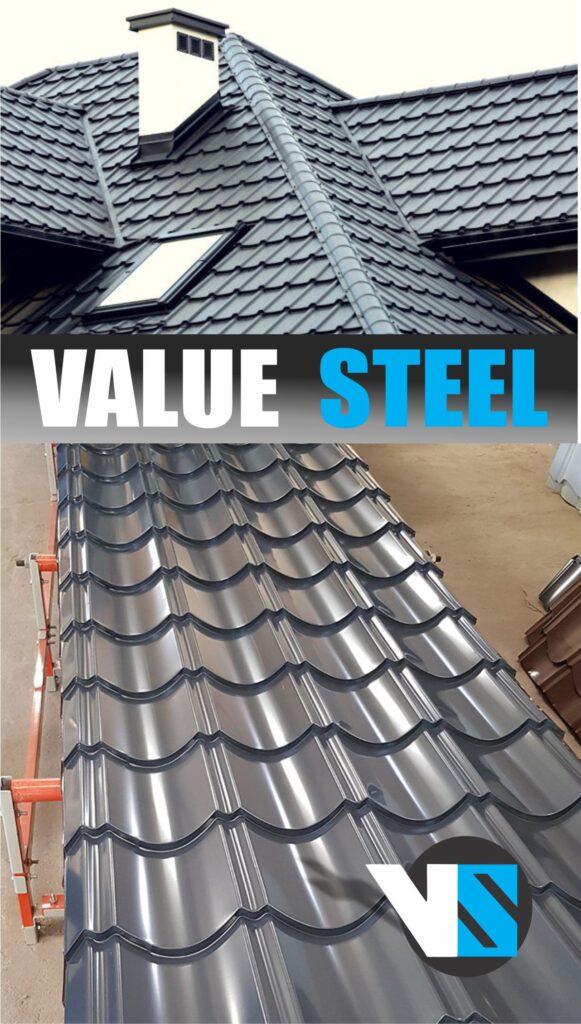

Thes coils are then sold to the market by companies like Value Steel Distributors and other Steel companies that either roll or contract out this to other companies that have a roller to manufacture the type of roof sheet you need. There are different type of machines each able to to do a specific function and some able to do more than one fuctions. Referring to function i mean the roller can manufacture an IBR sheet or s Corrugated sheets some can do both if you swap around the rollers. New designs have been intriducted that look like the old or classic ceramic tiles we all know so well.

CORRUGATED